The week has been slow as far as construction goes. Many things to do besides boat building but I did spend some time researching the choice of engine and installation.

When I first decided to build the Vera Cruise, I was interested in building a boat with an inboard engine but utilizing a sterndrive for propulsion. For those that might not be familiar with this, it is commonly seen on fiberglass boats purchased from boat dealers and is often referred to as an I/O (inboard/outboard). It consists of a drive unit that is attached to the aft end of the boat and which sets in the water. The drive unit connects through the aft end of the boat to an engine via a connecting drive shaft.

This drive unit swivels to control steering on the boat while tilting for trimming the boat when it is underway. Trimming for this type of boat means adjusting the angle the boat sets when it is at speed so that the bow of the boat is out of the water and the stern is riding across the water.

My other option for powering this boat was using an outboard motor. In fact the boat is actually designed for an outboard motor in the 35 to 125 horsepower range. Outboard motors, of course attach to the aft end of the boat and the entire unit is outside the boat. Like a stern drive it can be tilted and swivels for steering.

Outboard motors typically cost more than inboard motors because inboard motors are based upon automobile engines and therefore can benefit from the cost reduction inherent in mass production. Outboards, are specialized motors that are produced in far fewer quantities and therefore do not benefit as much from economies of scale.

Outboard motors are easier to install in boats and are popular for smaller boats for this very reason. They can be hung on the back of the boat and adjusted quickly for operation. Inboard motors require additional strengthening of the hull as well as mounting in an appropriate manner to transfer the stress of movement to the hullss structure.

Outboards and inboards both are noisy, but inboards are often installed in a padded and insulated engine compartment which cuts down on the noise. There are inboard designs that utilize larger engines and some where the engine is not covered, but the design I have in mind for my boat will be covered.

Outboard motors are also basically self contained (except for fuel and battery), whereas inboards require exhaust, fuel, cooling, and electrical systems to be installed. Even with the extra effort, the costs are less for an inboard with sterndrive (at least in the application I have in mind for my boat).

The design of the Vera Cruise , as I mentioned, was originally meant for an outboard motor. It has provisions for something called a motor well where the engine would be mounted. This motor well is designed to be self draining in the event that water gets up into it. It also serves as a part of the structure at the aft end of the boat.

However, the designer also has document showing conversion to an inboard/outboard drive. The provisions are not detailed in the building plans, but rather are general design instructions for converting an outboard boat to an I/O drive. For my boat that means using and engine and sterndrive combination that weighs less than 700 pounds. It also requires removing the motor well and replacing it with motor stringers and suitable structure enhancements.

The motor stringers are wooden beans that run fore and aft and are spaced approximately 26 inches apart. These beans are connected to the hull and provide additional strength to transfer the engine loads to the rest of the boat. The engine is mounted to other wooden components called motor beds which in turn are mounted to the motor stringers. The motor is also mounted to the transom (aft most bulkhead on the boat) where it also connects to the sterndrive through a hole in the transom.

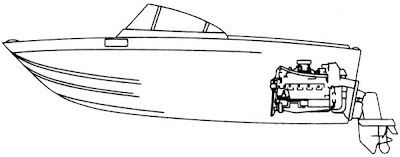

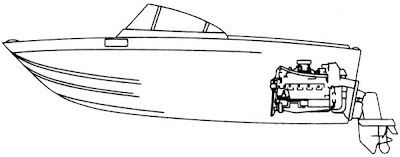

The following images illustrate the engine and sterndrive and how they set in a typical boat installation.

In the meantime, heres a teaser - Frame 5 initial assembly

Update 3/25/2013 - I realized that this article gives the impression that the engine choice is a done deal. Actually, I never was able to satisfactorily answer all the various issues with making the switch to an I/O drive. The main issues of weight on this size boat has me concerned that the boat will set too low in the water. Although Glen L Marine states that up to 700 pounds can be supported by this boat, I decided not to try and tempt fate on this particular issue. So I have decide to go with an outboard motor. No final choice yet, although I like the Yamaha 90 and 115 motors.

When I first decided to build the Vera Cruise, I was interested in building a boat with an inboard engine but utilizing a sterndrive for propulsion. For those that might not be familiar with this, it is commonly seen on fiberglass boats purchased from boat dealers and is often referred to as an I/O (inboard/outboard). It consists of a drive unit that is attached to the aft end of the boat and which sets in the water. The drive unit connects through the aft end of the boat to an engine via a connecting drive shaft.

This drive unit swivels to control steering on the boat while tilting for trimming the boat when it is underway. Trimming for this type of boat means adjusting the angle the boat sets when it is at speed so that the bow of the boat is out of the water and the stern is riding across the water.

My other option for powering this boat was using an outboard motor. In fact the boat is actually designed for an outboard motor in the 35 to 125 horsepower range. Outboard motors, of course attach to the aft end of the boat and the entire unit is outside the boat. Like a stern drive it can be tilted and swivels for steering.

Outboard motors typically cost more than inboard motors because inboard motors are based upon automobile engines and therefore can benefit from the cost reduction inherent in mass production. Outboards, are specialized motors that are produced in far fewer quantities and therefore do not benefit as much from economies of scale.

Outboard motors are easier to install in boats and are popular for smaller boats for this very reason. They can be hung on the back of the boat and adjusted quickly for operation. Inboard motors require additional strengthening of the hull as well as mounting in an appropriate manner to transfer the stress of movement to the hullss structure.

Outboards and inboards both are noisy, but inboards are often installed in a padded and insulated engine compartment which cuts down on the noise. There are inboard designs that utilize larger engines and some where the engine is not covered, but the design I have in mind for my boat will be covered.

Outboard motors are also basically self contained (except for fuel and battery), whereas inboards require exhaust, fuel, cooling, and electrical systems to be installed. Even with the extra effort, the costs are less for an inboard with sterndrive (at least in the application I have in mind for my boat).

The design of the Vera Cruise , as I mentioned, was originally meant for an outboard motor. It has provisions for something called a motor well where the engine would be mounted. This motor well is designed to be self draining in the event that water gets up into it. It also serves as a part of the structure at the aft end of the boat.

However, the designer also has document showing conversion to an inboard/outboard drive. The provisions are not detailed in the building plans, but rather are general design instructions for converting an outboard boat to an I/O drive. For my boat that means using and engine and sterndrive combination that weighs less than 700 pounds. It also requires removing the motor well and replacing it with motor stringers and suitable structure enhancements.

The motor stringers are wooden beans that run fore and aft and are spaced approximately 26 inches apart. These beans are connected to the hull and provide additional strength to transfer the engine loads to the rest of the boat. The engine is mounted to other wooden components called motor beds which in turn are mounted to the motor stringers. The motor is also mounted to the transom (aft most bulkhead on the boat) where it also connects to the sterndrive through a hole in the transom.

The following images illustrate the engine and sterndrive and how they set in a typical boat installation.

I initially had quite a bit of trouble deciding on whether to go with an outboard or I/O drive. As I said, my preference was the I/O but I couldnt find an engine and sterndrive combination that came in under the weight limitation. This was due to a mistake on my part when interpreting specifications for engines.

However, after searching and searching I found a diesel engine manufactured by Ford and sold in England but at a fairly high price. It also had the disadvantage of having to be purchased and shipped across the Atlantic, adding considerable cost to the purchase. I was also concerned about being able to get parts later on as the engine required maintenance. It was not exactly my first choice for a final engine selection.

One day, I happened to come across a website that specifically stated the weight of the engine and sterndrive of a Mercruiser 3.0 liter marine engine. The engine was equipped with a Mercruiser Alpha One sterndrive (which is what I was looking for). The engine and drive total weight was stated as 635 pounds. Further research verified this and I was satisfied that I had found what I was looking for. This motor has the advantage of being produced and sold in the United States as well as having been produced for a long time so parts are plentiful. Furthermore, it is in the correct horsepower range for my boat.

So this week I spent some time figuring out how the engine could be mounted in the Vera Cruise and with some help from a forum on Glen L Marines website, I was able to get the answers I needed. I determined that the motor stringers must be mounted above the lower frame parts and that they will need to run from the transom to at least the cabin. I may run them further after further evaluation of the plans.

The reason I wanted to get this question resolved is because I will eventually be building the frame parts for the transom and the design of that part will be somewhat different because of the drive choice I have made. The angle of the transom to the rear of the boat is slightly different and the structure will have to be strengthened as well.

Finally, I did get some additional materials I needed to start laying out and making the gussets for the frames. This only occurred this morning so for now I dont have much else to write about on that part of the project. So next time I will cover laying out and making the gussets.

In the meantime, heres a teaser - Frame 5 initial assembly

Update 3/25/2013 - I realized that this article gives the impression that the engine choice is a done deal. Actually, I never was able to satisfactorily answer all the various issues with making the switch to an I/O drive. The main issues of weight on this size boat has me concerned that the boat will set too low in the water. Although Glen L Marine states that up to 700 pounds can be supported by this boat, I decided not to try and tempt fate on this particular issue. So I have decide to go with an outboard motor. No final choice yet, although I like the Yamaha 90 and 115 motors.

0 ટિપ્પણી(ઓ):

ટિપ્પણી પોસ્ટ કરો